Supply Chain Optimization :- Automotive

The Client

Our Client is the world’s largest manufacturer of two – wheelers, based in India. In 2001, the company achieved the coveted position of being the largest two-wheeler manufacturing company in India and also, the ‘World No.1’ two-wheeler company in terms of unit volume sales in a calendar year. In India, it has a market share of about 46% share in 2-wheeler category. On 31 March 2013, the market capitalization of the company was INR 308 billion (USD 5.66 billion)

The Challenge:

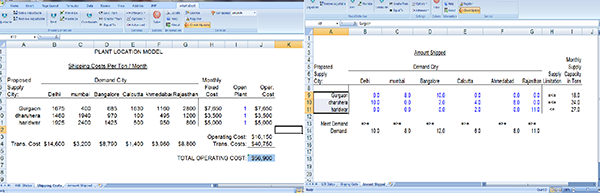

Our client has three manufacturing plants in Gurgaon, Dharuhera and the largest one at Haridwar. These plants together have a production capacity of 6.9 million 2-wheelers per year. The client has a sales and service network with over 3,000 dealerships and service points across India. The finished products from the manufacturing plants are to be transported to dealership network spread across India via trucks.

Given the shipping cost (per ton per month) associated, our client was facing challenges in selecting the manufacturing plant for how many no. of units to be shipped from the supply cities to the demand cities via road so as to minimize the total transportation cost keeping in mind both the capacity and demand constraints.

The challenge is to locate plants in such a way that demand is satisfied in each target city, potential plant capacity is not exceeded, and overall operating costs are minimized.

The Approach

Binary suggested the use of OR ( Operations Research) technique and the excel-based optimization tool What’s Best to develop a mathematical model incorporating various constraints of capacity, demand and cost. In the optimization model, the decision variables were designed to reveal how much quantity of monthly production were to be shipped from the manufacturing plants to the distributors across different cities. Manufacturing plants have a monthly supply capacity that must not be exceeded, Capacities of the transportation mode may be limited. In addition monthly demand of the distributors must be fulfilled.

The Benefit

This optimization solution improved the manufacturing and distribution efficiency which helped them to ensure a more robust supply chain.

Key benefits that company enjoyed:

- Demand – Supply is satisfied in each target city.

- Potential Plant capacity is not exceeded.

- Company gained visibility across its supply chain to mitigate Cost.

The client is well satisfied with the benefits of a well-designed system in terms of overall cost saving